Microseismic Geomechanics: Horn River Case Study

We are using recorded microseismic data from a hydraulic fracturing treatment in the Horn River Basin, Canada, to calibrate a geomechanical model in order to better understand fracture growth and proppant distribution. By quantitatively comparing observed and synthetic microseismicity (out of the geomechanical model), we can match the fracture dimensions and be confident in the results from the model.

The workflow is as follow:

- Create a geometric model of the reservoir and hydraulic fractures based on treatment well position and completion (number of perf clusters, spacing).

- Create the discrete fracture network (DFN) with orientations of the fractures inferred from microseismic event amplitude ratio inversion.

- Use logs to get mechanical properties (Young’s modulus, Poisson’s ratio, density) and stresses to initialize the model.

- Setup injection and proppant schedules for the model. Set leak-off coefficient.

- Run continuum models (without DFN) to fine tune stresses and injection parameters to match length of fractures.

- Validate observations by comparing synthetic and recorded microseismicity.

- Run models with varying parameters for sensitivity study according to client’s need, for instance change fluid viscosity, landing point...

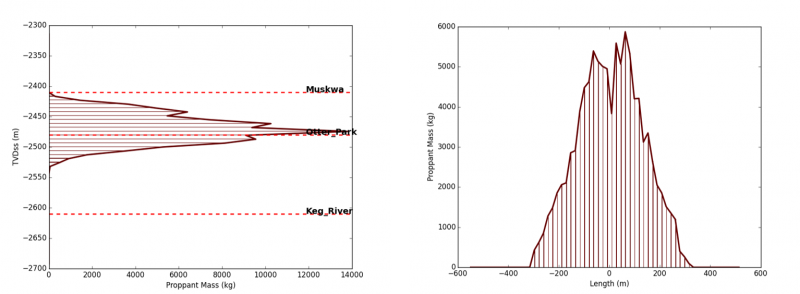

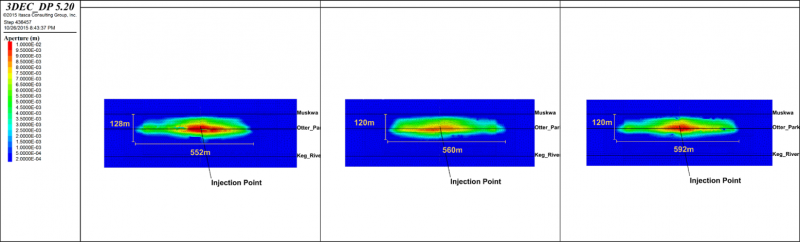

The data were provided by ConocoPhillips. The case study focuses on 1 stage with three, 25 m-spaced clusters. The fluid has a viscosity of 300 cP and was injected at a rate of 9.6 m3/min. The injection lasted 95 minutes. The figure below shows the aperture and extent of the hydraulic fractures out of the three clusters.

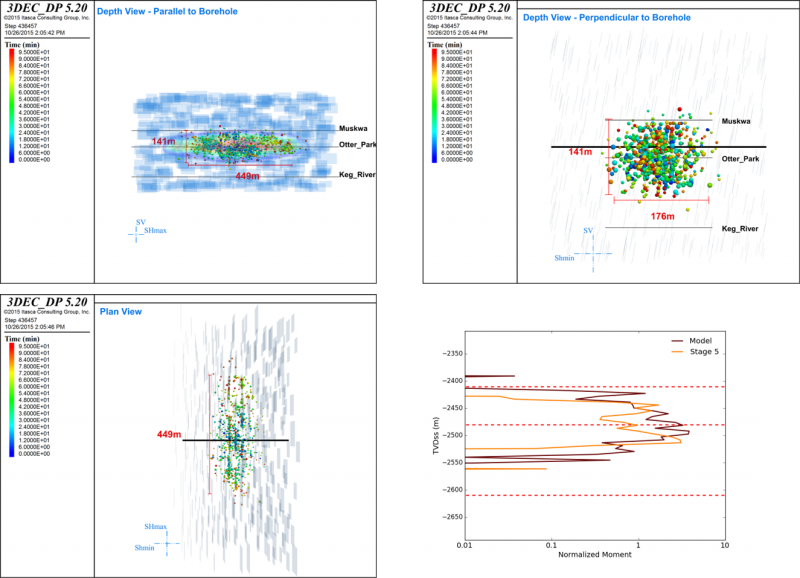

The geomechanical model will give exact locations of microseismic events. We are using statistical distributions of location errors from the recorded microseismicity to perturb those locations to get a more realistic picture of the microseismic cloud and better compare with the observations. We are also comparing the seismic moment distribution along depth (see figure below).

Finally the proppant distribution along depth and along the length of the hydraulic fracture can also be analyzed.